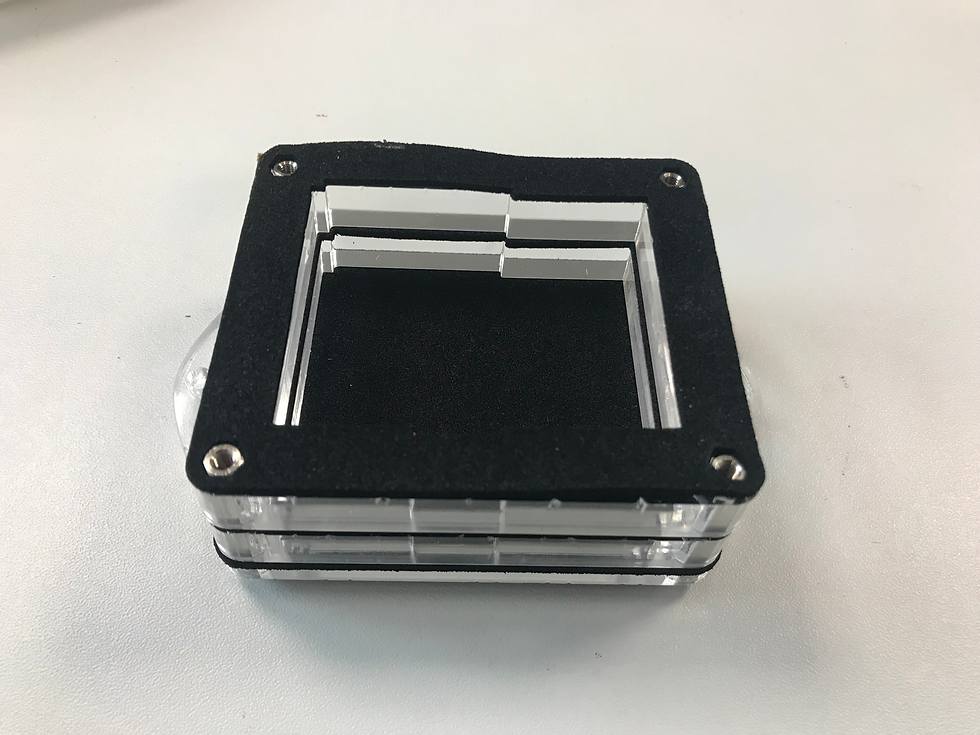

AA acrylic laser cut enclosure

- The Team

- Apr 24, 2019

- 2 min read

We have recently added the design files to enable users to cut their own acrylic enclosure. This acrylic enclosure can be laser cut using the pdf design files on the Resources page or the files can be used to order from any laser cutting service. Any laser cutting service can be used that supports 10mm acrylic sheets. For example, http://modelshop.co.uk/Static/WorkShop/Laser-Cutting-And-Engraving is a UK. The majority of services will accept pdf format, but if they don't the pdf can be edited in any graphic design software and saved to the preferred format of the laser cutting service.

To make the case you will need the following materials:

5mm acrylic (to make lid and back of enclosure)

10mm acrylic (to make the inner hollow layers of enclosure)

The enclosure can be built using the following instructions:

Lay out all of the components to make the acrylic enclosure.

Place the first 5mm acrylic cutout flat on a surface, with the four hex spaces inserted into each hex slot.

Place the first expanded neoprene gasket through the four hex spaces so it sits flush against the first acrylic layer.

Place the first 10mm acrylic cutout through the four hex spaces, with the SD and USB protrusion located in the top left corner.

Place the second expanded neoprene gasket through the four hex spaces so it sits flush against the second acrylic layer, with the SD and USB protrusion located in the top left corner.

Place the second 10mm acrylic cutout through the four hex spaces, with the SD and USB protrusion located in the top left corner.

Place the third expanded neoprene gasket through the four hex spaces so it sits flush against the third acrylic layer with the SD and USB protrusion located in the top left corner.

Place the configured AudioMoth inside the acrylic case so the SD card lines up with the protrusion in the 10mm acrylic cutouts.

Place the final 5mm acrylic sheet on top of the enclosure and make sure the drill hole lines up with the microphone.

Screw up the four top thumb screws.

Turn over and screw the last four thumb screws into the bottom of the enclosure.

Firmly screw up all thumb screws and stick the acoustic vent over the microphone hole.

This is super helpful — love that you added the PDF design files so people can DIY the acrylic enclosure or just send it straight to a laser cutting service. Using 10mm acrylic makes it feel sturdy too, and it’s nice that the files are easy to tweak if a shop needs a different format (way smoother than figuring it out like Crossy Road on a bad run 😅).